SEE THE DIFFERENCE

MAXIMISE YOUR WAREHOUSE

AND STORAGE FACILITIES

WITH COMBILIFT

Warehouse Products

NARROW AISLE FORKLIFTS CUSTOMISED

It can often be difficult to find a forklift to manoeuvre your unique product in a warehouse. Combilift’s customised approach allows our clients to specify various features on one forklift, enabling them to handle everything from palletised goods to long loads safely and with ease. Whether you handle steel, packaging or food and drink, Combilift’s range of specialised Material Handling products is guaranteed to meet your specific needs while increasing your productivity, saving valuable warehouse space and reducing product damage while operating in narrow aisles.

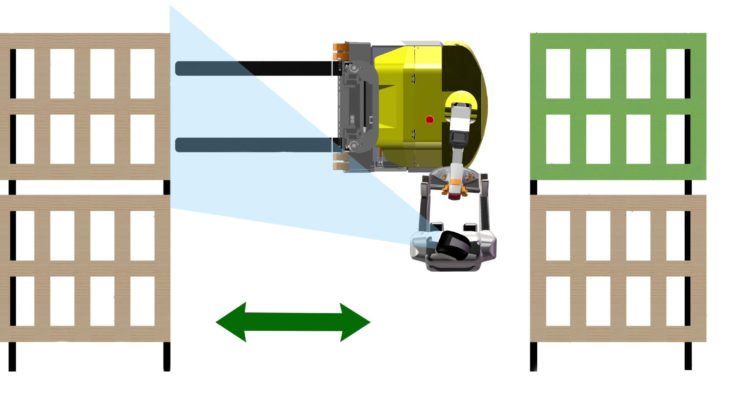

SMALLER AISLES

Combilift has the power to transform the way our customers look at storage. Powerful, precision lifting technology means Combilift can exploit every inch of vertical space while its ability to manoeuvre through narrow aisles and doorways means our customers can dramatically increase the amount of racking in their warehouses.

By optimizing existing storage, Combilift minimizes costs, environmental impact, and product damage improves safety and makes your business more efficient. Combilift’s bespoke approach means we can customize our products to meet the exact requirements of each individual customer, while our commitment to innovation and development means we are always looking for ways to push our technology even further.

MAXIMISE WAREHOUSE CAPACITY

Safety is at the core of each Combilift product for the operator, the load and the warehouse. The cabs in each Combilift forklift allows for 360˚ visibility meaning drivers can transport your products with confidence and in safety.

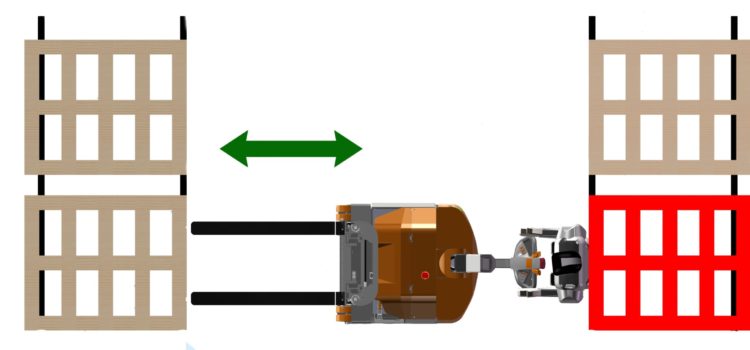

Models like the Combi-CS or Combi-WR/WR4 are quipped with our patented multi-position tiller arm the Combi-WR offers safer operation. The tiller can be turned to the left or right, allowing the operator to remain at the side, providing full visibility of the load and forks, while maintaining full steering control, enabling greater awareness of their surroundings which enhances overall safety. Standing to the side of the stacker eliminates the risk of being trapped or crushed while allowing the forklift to operate in very narrow aisles.

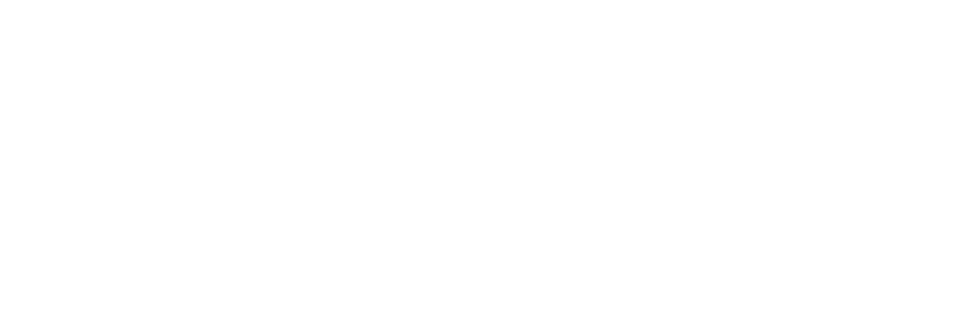

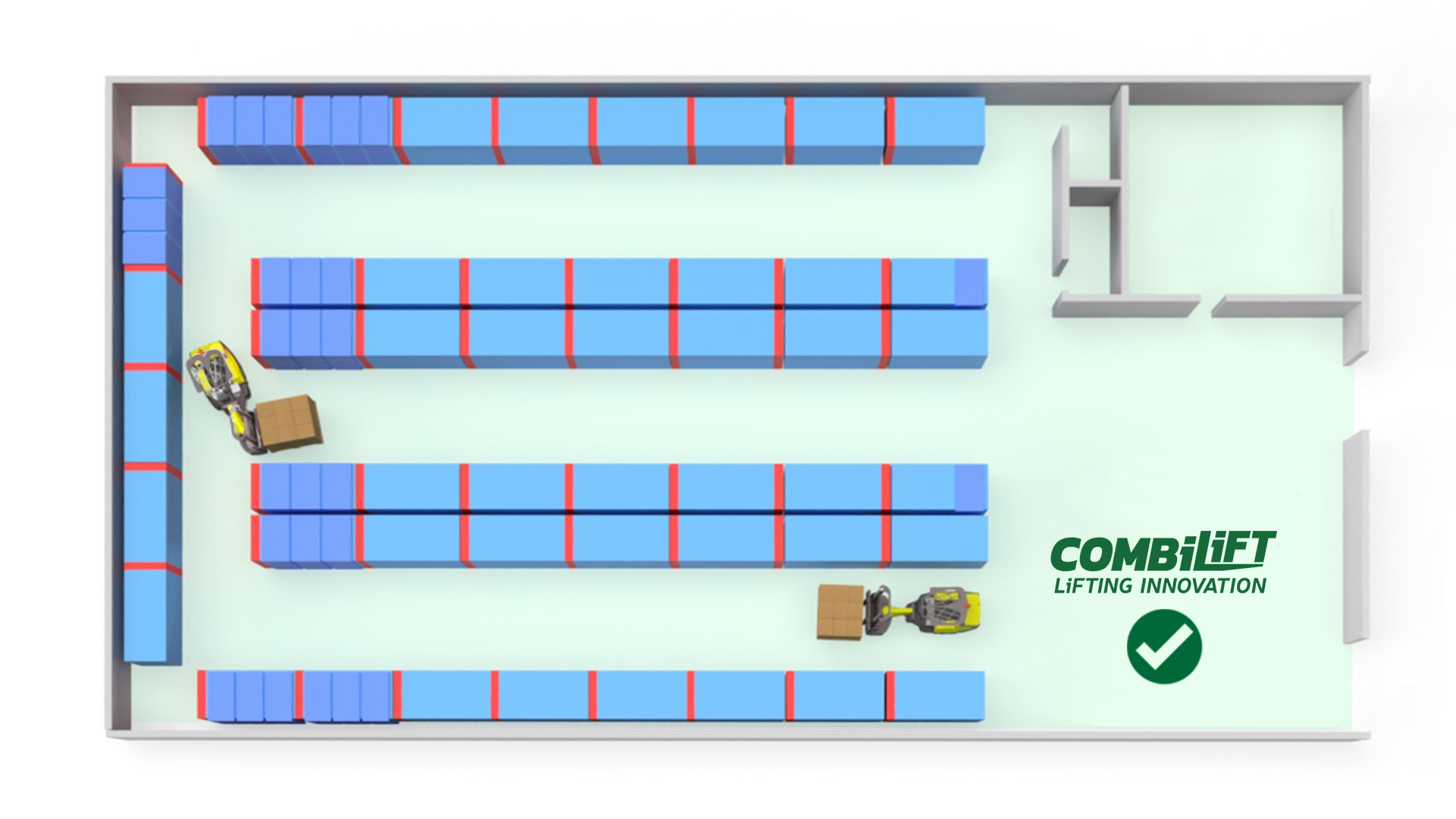

Without Using Combi-CS

Using Combi-CS

Aisle Master

With the ability to operate in very narrow aisles, VNA, in the warehouse – as narrow as 1.6m – the Aisle-Master articulated forklift increases and maximises storage capacity. What’s more, by using the one truck, users can increase productivity and eliminate time-consuming double handling and speed up “truck to rack” operations.

Aisle Master-OP

The NEW Aisle Master-OP (AME-OP) is a stand-on electric powered model that combines the advantages of a narrow aisle articulated forklift and an order picker for versatile operation in warehousing applications.

“We either needed to move premises or expand somehow. As it turned out, we didn't have to using Combilift. We got a Combi truck as well as more racking and it has doubled our storage capacity in our warehouse."Managing Director Andrew McCandles, Thermoseal Group

COMBI-WR/WR4

Its excellent ergonomics make it easy and stress free to operate. The unique patented multi-position tiller enables push button rotation of the rear wheel parallel to the chassis and back, allowing the operator to remain in the safest possible position when placing and picking in narrow aisles, namely at the side of the unit rather than between the truck and the racking.

COMBI-CS

Equipped with our patented multi-position tiller arm, the Combi-CS offers safer operation by providing full visibility of the load and forks, while maintaining full steering control, providing the user with greater awareness of their surroundings which enhances overall safety.

More videos of how our forklifts can optimize your warehouse space

SITE & WAREHOUSE OPTIMISATION

Find out more about how Combilift can manoeuvre palletised and long loads down narrow aisles, through standard doorways and around obstacles with ease, enabling racking to be placed closer together, reducing the amount of operational space required, and keeping your overheads down.