FOOD & BEVERAGE

Food & Drink Products

Combi-CS

Combi-WR

Aisle Master

Aisle Master - OP

REDUCING PRODUCT DAMAGE

Our forklifts of all sizes are designed for handling pallets of food in aisles as narrow as 1.6m, allowing you to increase your storage, efficiency and safety. Each forklift can be customised to fit all your business needs.

COMBI-CS

The patented multi-position tiller arm is a key feature for safer operation and narrow aisle performance. The tiller can be turned to the left or right of the unit to position the rear drive wheel, allowing the operator to remain at the side of the machine rather than at the rear.

This position eliminates crush risk for operators and allows full visibility of the load, the forks and the surroundings. With load capacities from 1000kg to 2,000kg this electric walk behind stacker can work in the smallest operating aisles for a machine of its type and lift capacity.

COMBI-WR

The unique patented multi-position tiller enables push-button rotation of the rear wheel, allowing the operator to remain in the safest possible position when placing and picking in narrow aisles, which is at the side of the unit. This improves forward visibility and greatly reduces the risk of incidents in tight confines. This and its excellent ergonomics make it easy and stress-free to operate.

“When we built the freezer a couple of years ago we realised that we needed a truck that would meet the demands of the low temperatures and the very narrow confines and the Combi-WR fitted the bill"said Logistics Manager Mark Cooley.

AISLE MASTER

Aisle Master trucks are tough, versatile and built to last. Designed to withstand heavy-duty use inside and out, each robust VNA articulated forklift truck is manufactured to the highest standards.

AISLE MASTER AME-OP

The NEW Aisle Master-OP (AME-OP) is a stand-on electric powered model that combines the advantages of a narrow aisle articulated forklift and an order picker for versatile operation in warehousing applications.

The main benefits of AC electric include enhanced performance levels, leading to increased pallet movements for greater productivity and improved acceleration and gradeability. There are also fewer wearable parts resulting in low maintenance and reduced downtime.

Read our Customer Stories

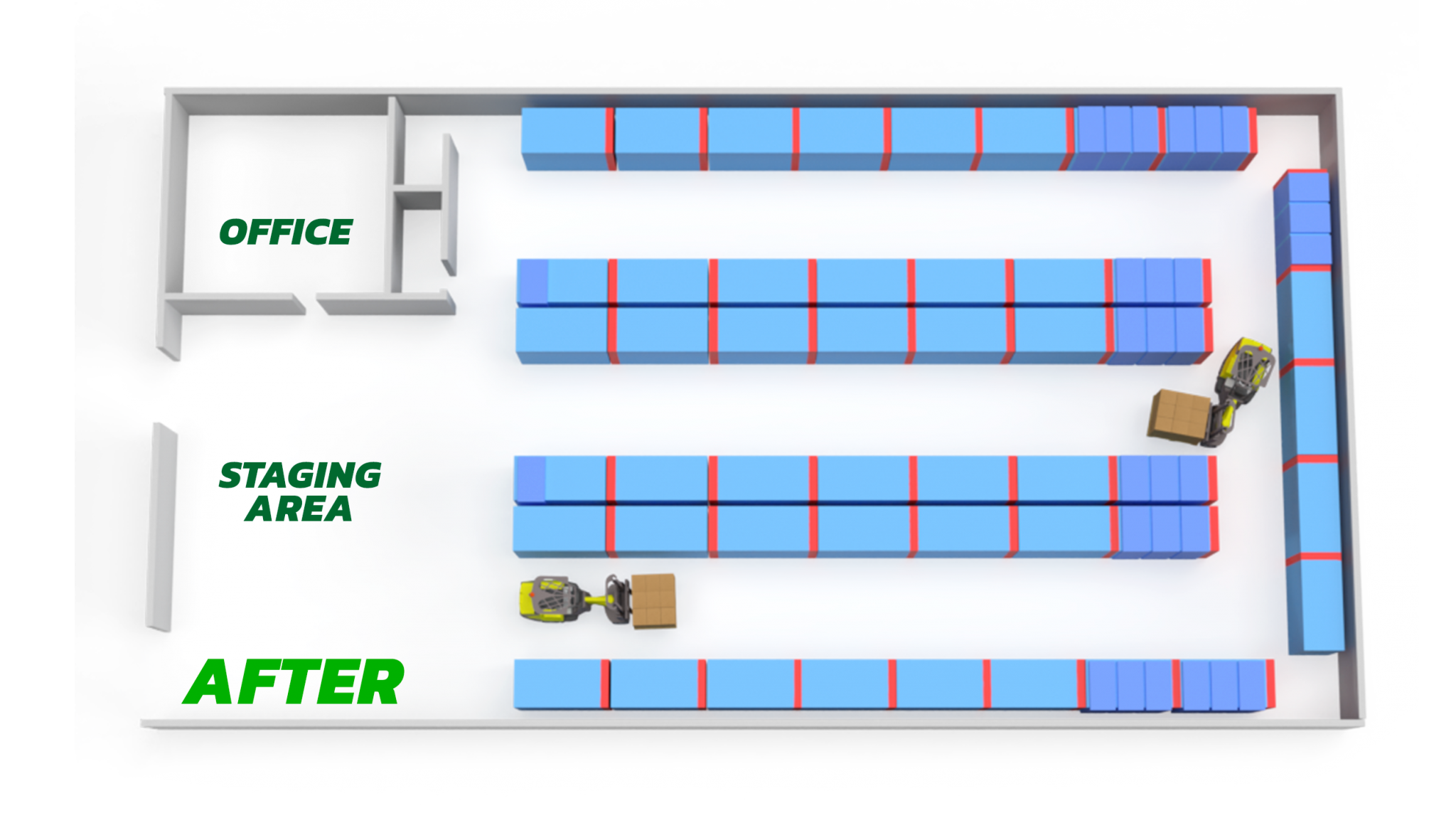

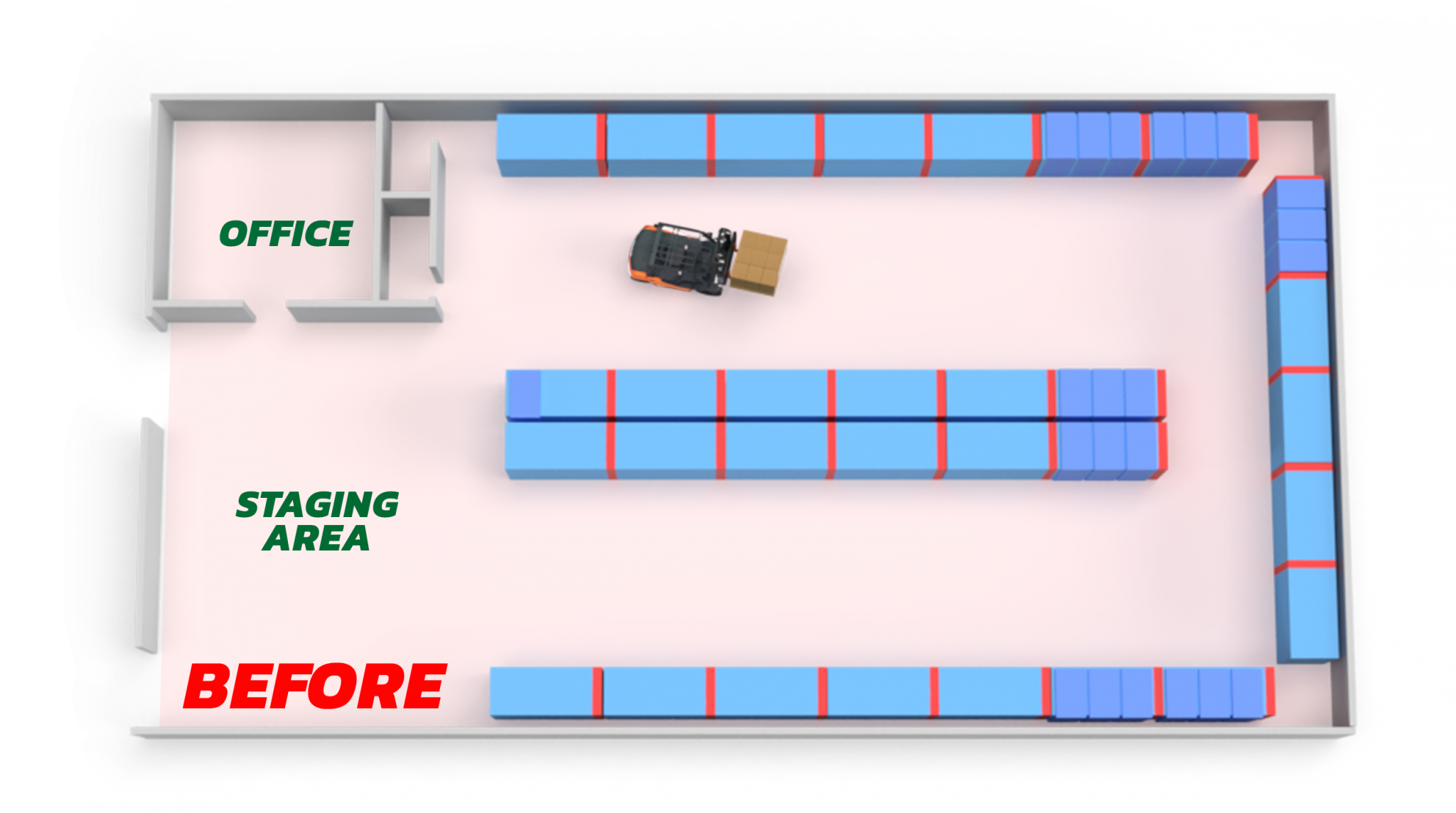

SITE & WAREHOUSE OPTIMISATION

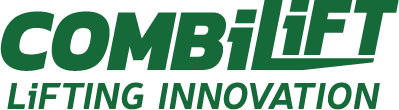

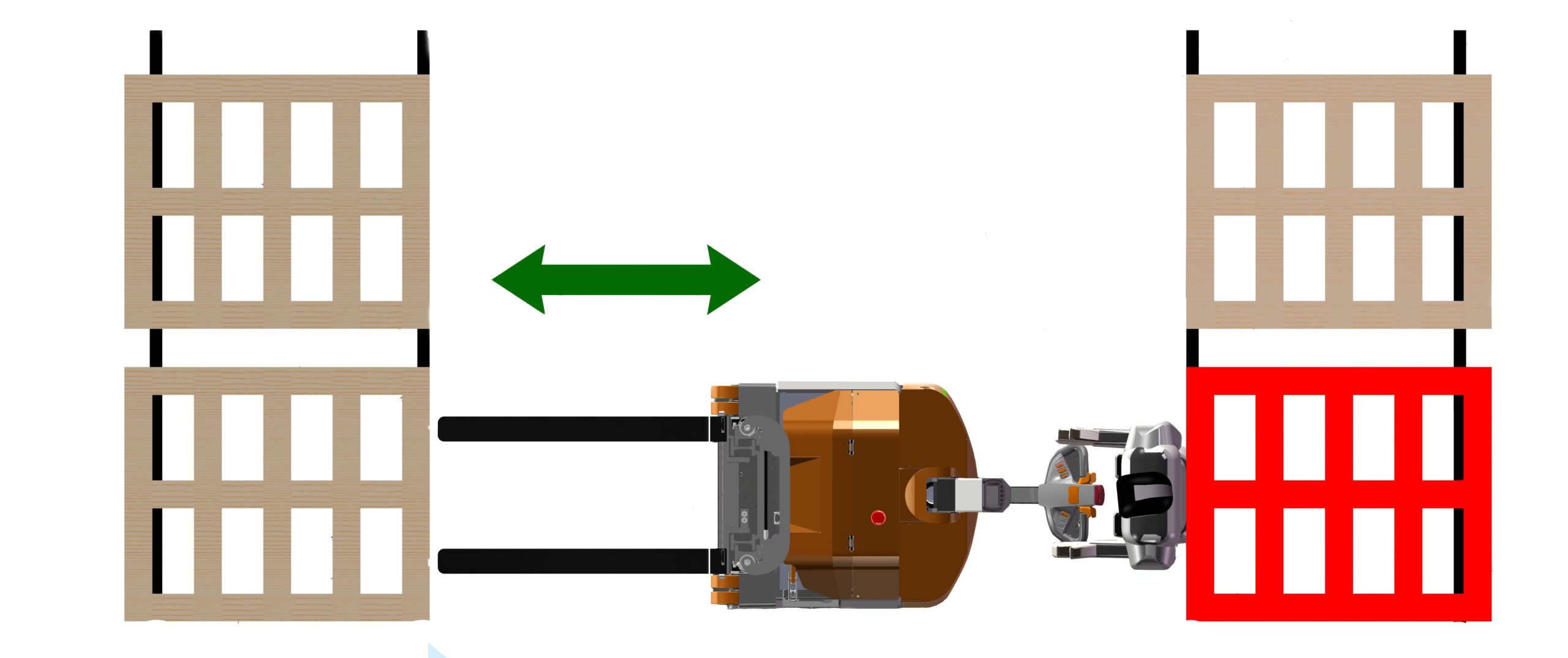

Find out more about the clever Combilift approach that enables the operator to change the direction of travel by 90 degrees at the flick of a switch. Seeing is believing, so we’ll show you how Combilift can manoeuvre even long loads down narrow aisles, through standard doorways and around obstacles with ease, enabling racking to be placed closer together, reducing the amount of operational space required, and keeping your overheads down.

SEE THE DIFFERENCE